Reducing the Impact of Unexpected Construction Expenses

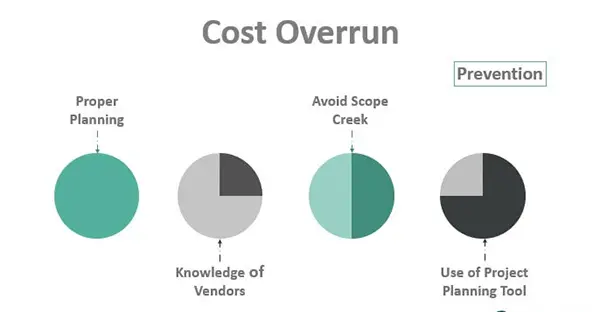

Encompassing a construction project is an exciting endeavor. However, there may be a few unexpected challenges that hinder the workflow. For instance, there can be unforeseen costs and delays. Further, project cost overruns are challenges that can lead to lost profit and dispute claims.

Behind this, several factors play a role in going over budget like site changes, material shortages, downtime, time management, regulatory requirements, unrealistic project planning, scope creep, etc. But, worry not! Fortunately, there are ways by which individuals can lessen the impact of those unexpected costs. Moreover there are various software available in the market such as Procore cost and Buildertrend cost which reduce unexpected construction expenses.

Once you are done reading this article, you can click on the following link to comprehend the benefits of employing ALICE for construction risk assessment.

Scheduling and Project Management

One must be aware of the fact that construction projects require careful and detailed planning. Even with budgeting and contingency measures. Therefore, after taking several precautions, unexpected expenses can still arise. Consequently, it will compromise the profit margins and financial viability of the project and business.

Whereas, management is something that can enhance efficiency and help in cost control. Poor scheduling and management can often result in delays which can seriously affect the timeline of the project. Its significant outcome can be increased labor charges, equipment downtime costs, material shortages, and many more.

Despite this, an overworked or tired workforce will most probably make mistakes, leading to unplanned work to correct errors (if any). Also, limited or inflexible budgets prevent quality control inspections.

However, low-quality work might require fixing later at a more significant cost. Altogether, these factors consequently result in contact loss or damage to one’s reputation.

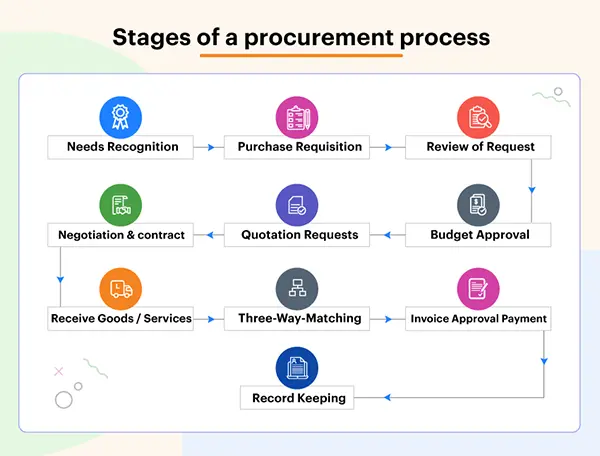

Material Procurement

Due to factory closures, geopolitical situations, supply chain disturbances, and enduring political strains, the material lacks and costs have risen. Considering this, contractors should undergo proactive measures in the procurement process itself.

Above all, mapping everything out and identifying areas of improvement can help them avoid scenarios like purchasing delays and issues relating to the delivery of construction materials.

Regardless, there should be open communication with clients relating to challenges that have come across to find alternative solutions. Even contractors are responsible for managing expectations, reducing conflicts, delays, and contract penalties.

Interesting Fact:

Lack or poor communication is considered the root cause of project failure one-third of the time.

Indeed, this will let both sides prepare for unexpected costs due to the shortage and strengthen business relationships.

Maintain a Skilled Labor Force

Maintaining a skilled labor force is paramount with regard to construction projects that require expertise and time. A shortage of skilled workers delays the completion of projects and increases costs. Likewise, to maintain quality staff workers, consider these factors noted below:

- Selective Hiring: The recruitment process comes first while looking forward to building and maintaining an efficient team of workers. Hiring skilled and experienced workers minimizes mistakes or efforts for rework. Certainly, because they can perform their duties competently.

- Continuous Training: Continuous training of hired professionals seems promising for building and maintaining an efficient team. Implementation of training programs is necessary to keep them up to date. For instance, they must be familiar with new construction techniques, safety procedures, or new equipment or materials.

- Competitive Compensation: Competitive compensation or salaries are major factors that can attract workers and retain top talents. Nonetheless, compensation must be commensurate on the basis of one’s level of skills and experience.

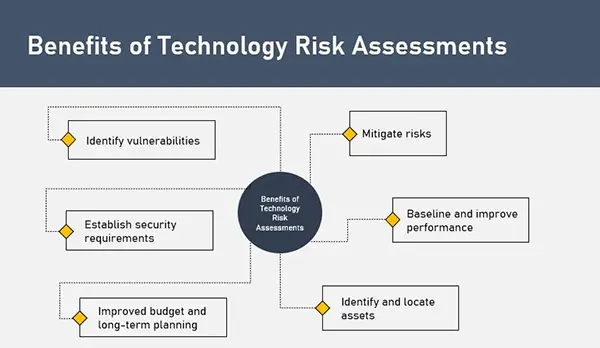

Utilize Risk Assessment Technology

Utilizing risk assessment technologies benefits in mitigating unexpected construction costs. Look below and understand how:

- Early Identification of Risks: Risk analysis tools potentially detect errors earlier in the project. It often allows the space for improvements or contingency plans before subjecting further additional costs.

Do You Know?

As per the Structure and Infrastructure Engineering Journal, most (approximately 50%) of projects’ overruns or reworks occur due to design errors and changes.

- Data-Driven Decision-Making: Tools can deliver more accurate predictions and informed decisions with the help of aggregated and analyzing data from past projects.

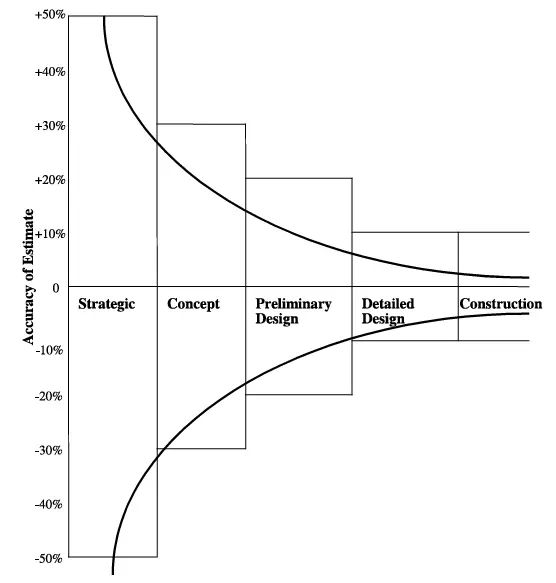

- Precise Project Estimates: The latest algorithms deliver accurate cost forecasts, hence reducing the likelihood of overruns because of underestimation.

- Enhanced Communication: Risk assessment tools facilitate improved communication within the team and with the stakeholders. Consequently, it ensures everyone is aware of likely risks and can work collaboratively on them.

- Automated Tracking and Reporting: This technology automates tracking and reporting of any upcoming risks. Hence, saves time and resources as well in comparison to manual processes.

- Improved Compliance Control: It helps to keep up with upcoming regulations. Thus, prevents expensive compliance issues, fines, and delays while ensuring the safety and regulatory measures are met.

Accurate Cost Estimation

Making accurate cost estimates mandates the understanding of price changes over time. Therefore, in order to understand price indices, construction material, and labor price index tools come in handy that show average changes.

It retains eyes on local marketplaces with which the tool can predict and schedule any further inflationary boosts in costs.

An agile supply chain responds swiftly to pricing fluctuations. Further, alliance-style contracts offer risk-sharing mechanisms to mitigate inflation’s effects on profit margins. It even emphasizes value beyond price like quality, speed, and business knowledge which eventually demonstrates non-monetary values to clients.

Avoid Scope Creep

Organized project scopes also help to reduce unwanted expenses. Vague project terms and requirements are considered the best considerations for scope creep.

Service companies or agencies might please their client base by undergoing modifications that are made to fit within their original parameters. Thus, it turns into an uncontrollable spiral of change.

Meanwhile, scope creep can lead to devastating repercussions for team morale, timing, and resources which can be avoided only by clear yet-to-the-point communication between stakeholders.

Don’t Let Unexpected Construction Expenses Affect Your Projects

Nevertheless, the management of unexpected expenses is quite complex. This is considered because it demands proactive planning and effective communication.

Often, it’s mandatory for contractors to prepare themselves for material procurement challenges, maintain a skilled labor force, and even leverage risk assessment technologies.

While handling projects with tight budgets, accurate cost estimation is vital for the prevention of spiral costing. With the Implementation of the strategies mentioned above, construction firms can efficiently navigate the industry’s uncertainties.

Exploring Common 2-Story Houses Energy Usage Patterns and…

How Long Does It Take to Obtain An…

The Secrets Behind High-Performance Racing Windows

Co-Parenting Strategies for Divorced or Separated Parents in…

How Auto Lawyers Help Victims of Distracted Driving…

How Can an Attorney Help in a Trucker…

What is the Rule of Thumb for Pipes?

Best DVD Rippers for Windows & Mac: Free…

8 Ways to Improve Wi-Fi Speed and Stability…

What Information Can Be Gleaned From a Funnel…

Essential Strategies to Make Hotel Management Easier

Puppy Power: Raising a Happy and Healthy Pup…